Whether you are a homeowner, or business owner, choosing the right toilet seat manufacturer is essential to ensure a high quality and long working life. In this digital age, finding a new supplier is not difficult, but finding a reliable and professional original toilet seat manufacturer is not easy. You can find that the market is flooded with countless manufacturers, all of which claim to offer the best products and services. However, not all manufacturers do as they said, making the wrong choice may lead to unsatisfactory purchasing experiences, and more serious is the possibility of losing money if buying inferior products.

The purpose of this post is to share some factors that you should consider when choosing a toilet seat manufacturer, ensuring that you make an informed decision.

1. Quality Assurance and Certifications

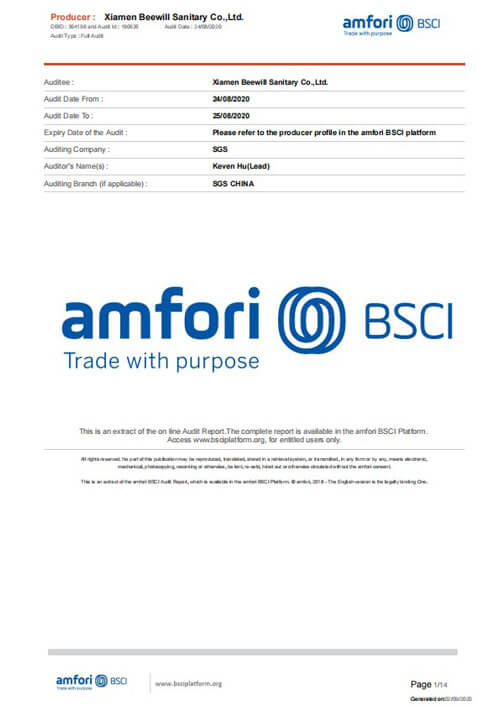

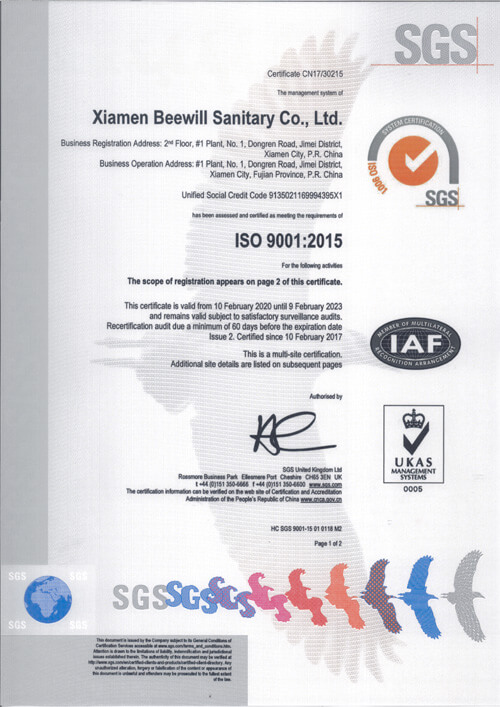

Quality is the most important factor that buyers consider, so quality assurance is many experienced buyers required when they face a new toilet seat manufacturer, but how do they ensure that? A reliable and reputable manufacturer usually has strict quality control protocols and robust relevant certification, such as ISO 9001, which ensures that their manufacturing processes meet international standards.

In addition, a toilet seat manufacturer with rich production experience, during their service for other existing customers in the past many years, must be required to accept some audit by the third authority parties, for example, BSCI, Sedex, FSC, etc, and will certainly be required to provide some test reports from the third parties, for example, TUV, ITS, SGS, etc, the tests including for raw material, package or products, that may include chemical or physical testing.

For this point, Beewill Sanitary has a strict quality control system, click quality control to read more details. And we are identified as a reliable and professional toilet seat manufacturer certificated by ISO 9001:2015, audited by BSCI, Sedex, FSC, even Amazon, etc.

Manufacturing Processes and Materials Used

You can find that toilet seats can be made of different materials, for example, duroplast, wood, PP, bamboo, stainless steel, or PVC soft material, etc. The different materials mean different manufacturing processes.

However, even with the same duroplast toilet seats, we can find that the workmanship of toilet seats could be different in different factories. For example, we know that all factories produce duroplast toilet seats by compression molding, but why the surface smoothness is different? some seats’ surface is rougher, and some seats are very smooth on every side and corner. It is because of the different polishing processes and standards.

So understanding the manufacturing processes is crucial to evaluate the quality and durability of their toilet seats. Also, the material used is important, take duroplast as an example, high-quality toilet seats are typically made from durable materials, and particle is better than powder UF material. Using good duroplast material can produce anti-bacterial toilet seats, because, after a proper molding process, the toilet seat surface is very hard and high density. For this point, Beewill always choose the high-quality duroplast material, and we tested our toilet seats by SGS, the anti-bacterial rate is higher than 99%.

Talking about this point, here I would like to share how Beewill promises the material used high quality. The molding process is the key process for duroplast toilet seats, so we are paying a lot of attention to this process. Firstly we do a molding test when the raw material arrives, and so to make sure the material is qualified for production. And then after the seat is molded, every seat will be checked on surface quality and structure. Besides, we also do boiling test and load test for every batch. Here I’d like to introduce more about boiling test:

The compression molding of duroplast toilet seats is a complicated process of chemical reaction. Sometimes if the procedure is not perfectly done, there will be still many small pin holes on the surface of seat cover. We cannot see from our eyes, but they exist. And these pin holes will absorb water afterward and may lead to breakage after use for a period of time. And so for every batch, we took the 1st piece from production, and cut the seat into small pieces, we then put it in blue ink and boiling for 30mins, to see how much ink got into the material. With this test, we can be sure if the pressing procedure is well done or not.

3. R&D Ability and Customized Service

If you have a specific design or require a customized toilet seat for your project, it is essential to see if the manufacturer has a strong R&D ability and offers a customization service.

To confirm this point, you can check from the following serval sides:

- Check how many engineers are in R&D team, to some extent, a large team indicates the company’s emphasis on research and development

- Require the manufacturer to provide their own design products and see their newest featured products.

- Check how many patents the manufacturer has, and whether it is difficult to get these patents.

- Understanding their processes of developing one new toilet seat model.

Beewill has a strong R&D ability, with 12 professional engineers, every year we shall develop some new products to meet the demand of the market. Normally to develop a new seat model, we can finish the drawing in 3-4 days, then another 3-4 days for the prototype. After the confirmation of the prototype, the tooling can be completed in 30 days. So you can see from an idea to a final product we can realize it in about 40 days. Our existing customers are quite happy with our service and efficiency in new product development.

4. Pricing and Payment Terms

Price is a significant consideration for each buyer. Obviously, in this networked age, where options abound and competition is fierce, the cost for each piece of raw material is transparent, which leads to suppliers won’t quote a ridiculous price if they want to be selected. Under this kind of situation, to get more orders, we believe that most manufacturers tend to quote their price based on the real cost plus a reasonable profit. It is a benign market environment, that helps buyers to select suitable products for their own market.

Additionally, consider the payment terms. Usually, the payment terms are negotiable, and it can be adjusted at different cooperation stages between the suppliers and buyers. According to the customs of international trade, for new cooperation, 30% deposit when placing theorder, 70% balance payment before shipment. This payment terms is selected for most suppliers. Before arranging the balance payment, you can arrange the 100% inspection to make sure that the goods align with your order requirements. And, if you want other payment terms, the toilet seat manufacturers will evaluate their cost and risk based on the order details. After some cooperation, both the buyers and suppliers can trust each other, and the payment terms can be adjusted to better support each other, for example, 100% payment before shipment, or arranging the payment at the sight of scan bill of landing, or even longer payment periods.

5. Production Capacity and Lead Times

If you have an urgent project or large volume orders, inquiring about the manufacturer’s production capacity and lead time is important.

Assess their product capacity and whether they can handle your order efficiently, you can check how many workers and production lines they have, and how many pieces each production line can produce per day, then you can calculate how many days your order needs to produce. According to the production arrangement, when start to produce your order, and you can see if the lead time can meet your project deadlines.

In Beewill, normally, for order quantity around 1*20GP, our lead time is 30~45 days after order confirmation, and 1*40 GP, our lead time is around 45~60 days. The higher quantity we need to check the real production arrangement.

6. After-sales Service and Warranty

Excellent after-sales service and a longer warranty can show a manufacturer’s comprehensive strength, and it also shows the supplier’s confidence in their quality from another perspective. A toilet seat manufacturer that stands behind their products and offers comprehensive after-sales support is a valuable partner in your toilet seat business.

For this point, actually, it seems hard for buyers to get the guarantee. But you don’t need to worry if you cooperate with Beewill. For Beewill UF / Duroplast toilet seats, our warranty is 5 years, and for PP seats, our warranty is 3 years. And we guarantee that our toilet seats can conform to the standards of DIN 19516, which is the most strict standard in Europe. For your information, our routine handling procedures for customer complaints are as follows:

- Confirm the batch information of the claim seat and check the reserved samples. For each shipment, normally we keep 2~3pcs in house for at least 1 year for traceability purposes.

- Customer helps to check the date information on the buffer housing. There is a date mark in the buffer housing for each seat.

- For the functional issue, we recall a claim sample for checking and evaluation on our charge.

- If confirmed to be our responsibility, we will supply a free replacement.

Summary

It is hard to say all the details of manufacturing processes in this article, and we are not familiar with other factories’ processes, Also, not the highest price is the suitable one, or the lowest is the most suitable one. Different markets need different products like the high-end market needs high-end products.

If you are looking for a new toilet seat manufacturer for your project, we suggest visiting the factory on-site, after comparing several factories and learning about their internal standard, you can figure out who is the best supplier for you. And, we warmly welcome you to visit us, just feel free to contact us by filling out the below form.