Beewill’s Lab

Testing is a good way to know and control toilet seat quality.

Beewill can do a lot of tests in our own lab, and the testing standards mainly originated from DIN 19516 standards, some we also consider NF standards, China national standards, and US standards, and some we learn from our customers.

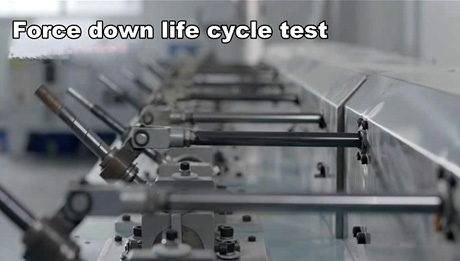

- Life cycle test: we can guarantee 100,000 cycles, equivalent to 10 years under normal use.

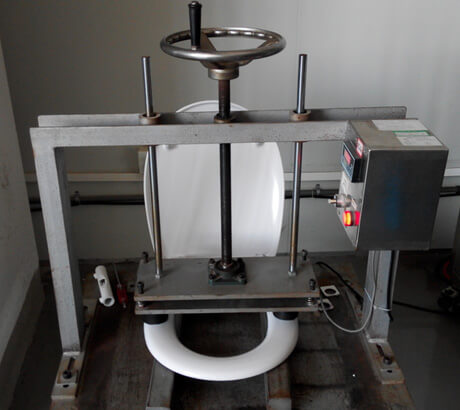

- Load test: 175 kgs to be applied on a closed top cover, the load lasts for 3 mins without breakage. Many of our seats can bear a load of even more than 300 kgs.

- Impact test: A load of 75kg drops freely from a height of 30mm. This process shall be repeated 15,000 times without any interruption. After testing, there should be no breakage or deformation.

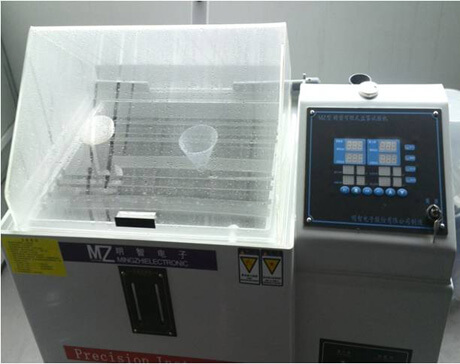

- Salt spray test (corrosion test): This is mainly for metal parts and chrome-plated parts. Our internal standard is CASS 8 hours, which is equivalent to 200 hours according to standard ISO9227:2012.

- Side movement test: This is a very strict test under DIN 19516, by applying 30 kgs pull force on a single side of the seat ring, and pulling it sideway. The movement of the front of seat should not exceed 10mm.

Besides these, we also have some special tests that we learn from our customers. For example, we do a kind of back pull test, which is from TOTO; and a kind of side pull test, which is from ROCA.

0

Production Lines

0

Square meters of production mall

0

Monthly Production Capacity