In today’s competitive market, having reliable partners for product development is crucial. At our company, we pride ourselves on being a leader in OEM toilet seat manufacturing. In this article, we will dive into the multitude of advantages our company offers, highlighting our dedicated team, short development cycles, exceptional quality assurance, collaborative business model, professional experience, comprehensive project management system, successful partnerships, and commitment to confidentiality.

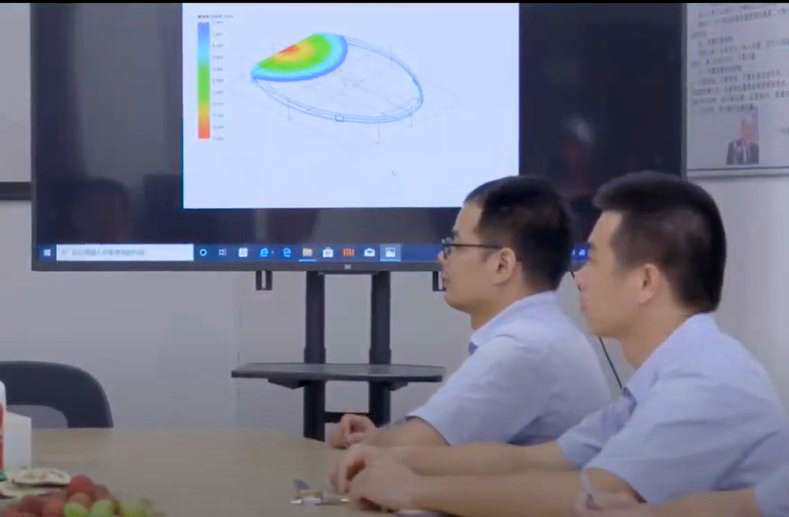

1. Strong R&D team design for your project

One of the foremost advantages of our OEM toilet seat development is the strength of our team. At the helm is our Chief Engineer, Mr. Ren, who boasts over 20 years of experience in the industry. He is not just an engineer, he is the inventor of the 1st slow-closing mechanism and the 1st one push button quick-release and slow close hinge in China. Although many competitors now provide toilet seats utilizing similar systems, we hold the original patent, which can be verified through public records.

Our R&D team consists of 12 specialized engineers with extensive experience in OEM toilet seat project development. This wealth of expertise allows us to address our clients’ unique challenges and provide comprehensive, professional product solutions. Whether it’s through innovative designs or tailored adjustments, our team’s knowledge ensures that your needs are met efficiently.

If you have a project in mind, we invite you to send an email to our address ” info@toiletseats.cn “. This will help us understand your requirements better and provide you with personalized assistance.

2. 40 days to develop a new toilet seat mold

Another significant advantage of partnering with us for custom toilet seat design is our in-house mold factory, which allows us to maintain an exceptionally short development cycle. Unlike many manufacturers who outsource mold creation, we handle everything internally. This operational efficiency enables us to complete designs in a short time. Here’s our typical timeline:

- Design Completion: Approximately 3 days.

- Prepare Prototype Sample: Around 1 week.

- Mold Production: Roughly 1 month.

The entire mold creation process typically takes about one month. This means that from a concept to a finished product, clients can expect to see the final product in as quick as 40 days. For businesses looking to bring innovative toilet seat solutions to market rapidly, this speed is essential.

3. A toilet seat mold can produce >300,000 pcs

Quality is at the forefront of our operations. We primarily serve the European market, with Germany being our largest market. Our strict quality control system ensures that we consistently supply high-quality products that meet international standards.

Our molds are engineered for durability, with a lifespan of up to 300,000 uses. Furthermore, we have a dedicated maintenance and improvement team focusing on keeping our toilet seat molds in optimal condition.

By prioritizing quality, we assure our customers that they are investing in products that will provide longevity and reliability. This focus on high-quality toilet seats not only builds trust but also supports brands in maintaining their market reputations.

If you’re excited about starting a project, don’t hesitate to contact us via email at info@toiletseats.cn.

4. Never let a 3rd party know

In the realm of OEM manufacturing, protecting client designs and proprietary information is paramount. To this end, we take confidentiality seriously. At the outset of our projects, we sign non-disclosure agreements with clients to guarantee that all designs and related information remain confidential. This commitment to privacy fosters a trustworthy relationship and reassures clients that their innovations will be safeguarded.

5. Help to improve your toilet seat designs

When clients come to us with their requirements, we don’t just deliver what they ask for. We provide our professional insights and recommendations. Leveraging our extensive industry experience, we help clients make informed decisions regarding their toilet seat designs. This consultative approach not only aids in the selection of materials and features but also enhances the overall design process, ensuring that the final product meets both aesthetic and functional criteria.

Our goal is to empower clients with the best possible solutions to help them stand out in the competitive bathroom fixture market.

6. Never lose your project details

To enhance our efficiency, we implement a dedicated project management system that meticulously tracks every phase of product development. From initial concepts to the communication of revisions, every detail is logged to guarantee coherence throughout the process. Regular meetings are held to review progress, enabling teams to address issues promptly and keep projects on track.

For extended projects, some lasting as long as 3-5 years, this system is invaluable. It ensures all relevant information is retained and communicated effectively among the team. Additionally, we provide a checklist upon project completion to ensure all objectives have been met and nothing has been overlooked.

7. Customize toilet seat molds for you, also for big brands

We have a proven track record of successful collaborations. Currently, we work with many prestigious ceramic factories, including renowned brands like Bemis, on multiple OEM projects. These partnerships not only demonstrate our credibility but also our capacity to meet varying client demands while adhering to high standards of quality and service.

Highlighting these successful projects in our marketing efforts allows potential clients to feel confident in choosing us for their OEM toilet seat needs, knowing that they are partnering with an experienced manufacturer.

8. Not only one sales service for you

Our approach to client relations is rooted in teamwork. For each project, we assemble cross-functional teams comprising various business professionals. This collaborative model allows us to provide comprehensive support to our clients. In scenarios where a team member is unable to engage, others can seamlessly take over, minimizing communication redundancies and ensuring continuous support.

Moreover, we understand that technical issues can arise during the development process. Our teams possess the capability to conduct video conferences with clients, providing real-time technical support and making adjustments as needed. This proactive approach makes us a reliable partner for OEM toilet seat manufacturing.

Conclusion

In summary, our company stands out in the OEM toilet seat manufacturing market for several compelling reasons. From the depth of expertise in our team, the efficiency of our development cycle, our unwavering commitment to quality, and collaborative business approach, to our focus on professional recommendations, meticulous project management, proven success stories, and dedication to confidentiality—every aspect of our operations is designed to support our clients’ success.

By choosing our company for OEM toilet seat development, clients gain a partner who is fully committed to helping them navigate the complexities of product development in the bathroom fixture sector. Together, we can innovate and elevate the standards of toilet seat design, ultimately contributing to a more user-friendly and aesthetically pleasing bathroom experience. If you are considering an OEM project, we invite you to reach out and discover how we can bring your vision to life.