In different product markets, people develop corresponding product standards to buy products with guaranteed quality. For example, WC seats, as we know, the German market has relatively high requirements of products, and it has released the complete standard and testing methods for toilet seats a long time ago, that is DIN 19516, the latest version was released in 2004.

Although DIN 19516 is the German standard for toilet seats, so far it is a common using standard for WC seats all over the world, not only in Germany now.

As a toilet seat manufacturer, we will not talk about complicated full lists under the DIN 19516 standard. In this article, you will just learn the normal standard you need to know when purchasing toilet seats.

For toilet seats, let’s see the overview of DIN 19516 requirements and test methods.

4.1 General Information

The manufacturer shall provide instructions for installation and maintenance.

Appendix A provides guidance for the creation of installation and maintenance instructions in the manufacturer’s accompanying documentation can be considered.

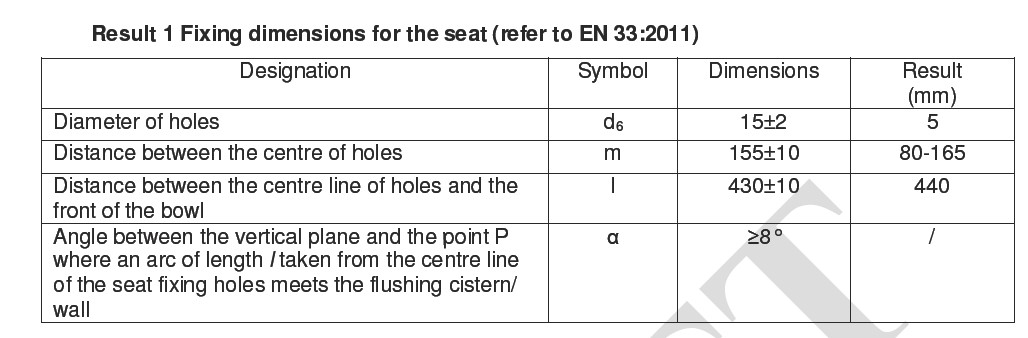

4.2 Connecting Dimensions

The connection dimensions must meet the requirements of DIN EN 33, EN 34, EN 37 and EN 38th.

4.3 Product Dimensions

The dimensions of the lid and / or seat ring and the overall product may vary in relation to the information in the product documentation by no more than ± 2 mm.

4.4 External Quality

When viewed with the naked eye, the inner and outer surfaces of the toilet seats smooth and free from cracks, blisters, or other surface damage must be that affects their function.

Toilet seats should be free of sharp points, sharp edges, and burrs.

The design of the components of toilet seats must ensure easy accessibility for cleaning purposes.

4.5 Rigidity

When used, WC seats must feature stability, which gives a safe feeling while sitting. The rigidity of the used material should be proven with regard to resistance against static and dynamic loads.

These requirements will be regarded as being met, if during the test according to 5.3.3 Test A, Tests B, Test C, and Test D.

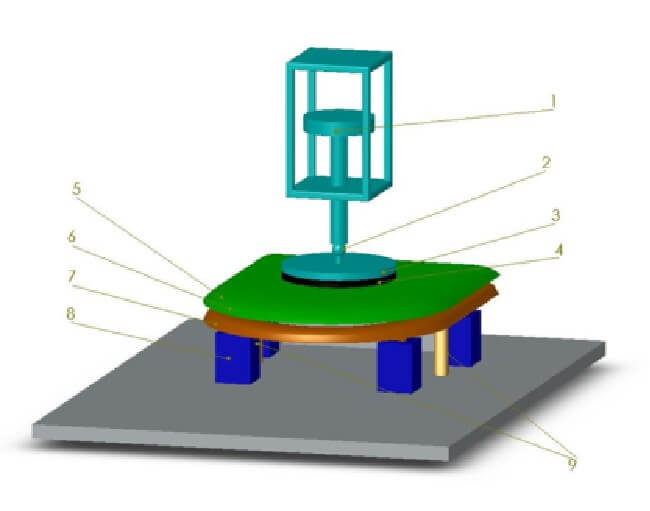

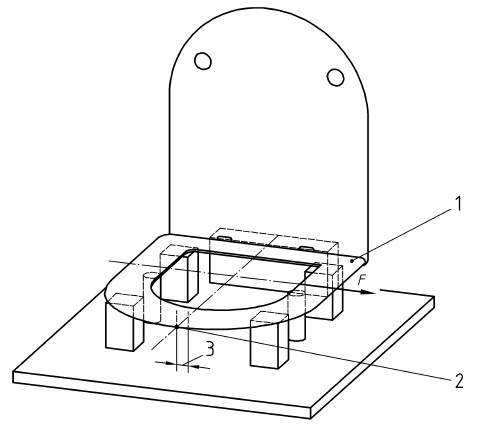

Test A: Static load test of the closed top cover

Test method: The toilet seat is fixed with a torque of (2.5 ± 0.5) nm as shown below, a load of 75kg is to be applied within 7.5 +/- 0.5s on the geometrical center of the cover of the test sample by a loading pad with a diameter of 160 +/- 10mm for 60 +/- 5 s.

After removing this load, a load of 175kg is to be applied within 15 +/- 5 s on the geometrical center of the cover of the test sample by a loading pad with a diameter of 160 +/- 10mm for 180 +/- 5 s.

Requirement: No break, tear, or permanent deformation was found after the above test.

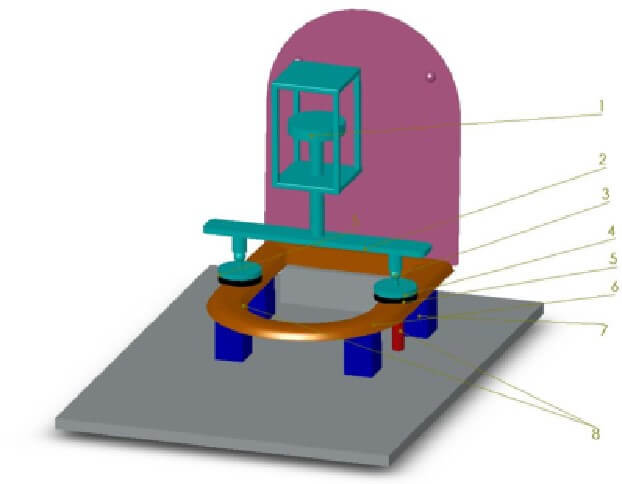

Test B: Static load test of the seat ring

Test method: The toilet seat is fixed with a torque of (2.5 ± 0.5) nm as shown below, a load of 75kg is to be applied within 7.5+/- 0.5s on a cross beam presented over the geometrical center of the cover of the test sample by two loading pads with a diameter of 75+/- 5 mm for 60+/- 5 s.

After removing this load, a load of 150kg is to be applied within 15+/- 1 s on a cross beam presented over the geometrical center of the cover of the test sample by two loading pads with a diameter of 75+/- 5mm for 180+/- 5 s.

Requirements: No break, tear, or permanent deformation was found after the above test.

Test C: Static load test for one-side of the seat ring

Test method: The toilet seat is fixed with a torque of (2.5 ± 0.5) nm as shown below, a load of 75kg is to be applied within 7.5+/- 0.5s on the seat ring by a loading pad with a diameter of 75+/- 5 mm for 60+/- 5 s.

After removing this load, a load of 75kg is to be applied within 15+/- 1 s on the seat ring by a loading pad with a diameter of 75+/- 5mm for 180+/- 5 s.

Requirements: No break, tear , or permanent deformation was found after the above test.

Test D: Dynamic load test of the seat and cover

Test method: The toilet seat or seating ring was assembled according to instruction. The hinge screws shall be tightened with a torque of 2.5±0.5 Nm. A loading weight of 75kg drops freely down from a height of 30mm. This process shall be repeated with a speed of 10 to 15 cycles/min for at least 15000 times without any interruption.

Requirements: No break, tear, or permanent deformation was found after the above test,

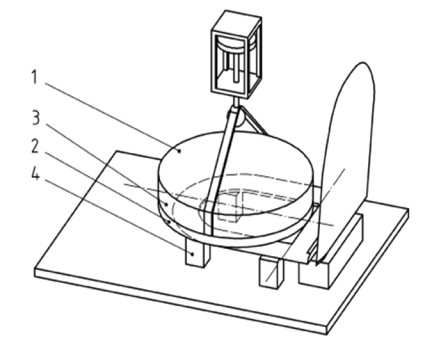

Test E: Life cycle test

Test method:

1. Assemble the seat cover onto the machine.

2. Turn on the power of the machine. A pushing rod will raise the seat cover to a vertical position and then lie against the supporting board in the back.

3. Another pushing rod pushes the cover from the back and lets it close freely until

it closes completely. This way finishes one cycle.

4. Keep testing for 15,000 cycles.

Requirements: The tested cover & seat & hinges had no damage after being tested 15,000 above cycles.

Test F: Side movement test

Test method: Make sure the toilet seat is well fastened on the testing platform, a horizontal force of 300N±10N is applied to the center of the seat ring, the hinge is held in the fastenings and the lateral displacement does not exceed 10mm.

This is a very strict test under DIN 19516, by applying 30 kgs pull force on a single side of the seat ring, and pulling it sideway. The movement of the front of the seat should not exceed 10mm. In the real situation, most customers can accept within 20mm.

As a toilet seat manufacturer, Beewill always takes quality as the most important factor for our enterprise development. In our quality control system, we require higher standards than DIN 19516 requirements. For example, we can guarantee 100,000 cycles for the soft close function, which is equivalent to 10 years of normal use.

Any more questions about the WC seat test requirements, please feel free to fill below form to contact us.